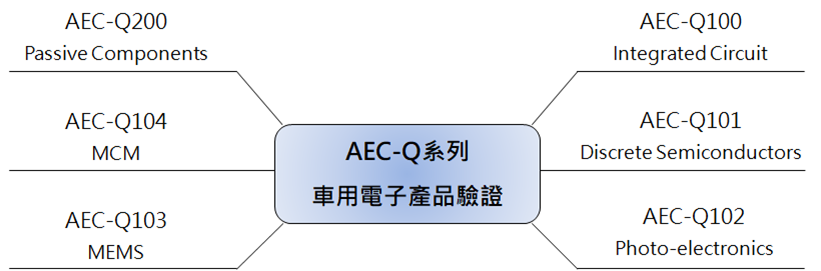

車用電子可靠度試驗

車用電子協會(AEC,Automotive Electronics Council)為了讓電子元件的驗證有一個共同的參考驗證內容,因此根據產品類別陸續制定了不同驗證標準,讓各家電子元件廠商欲進入車用市場時,有一個適當的驗證基礎。

在AEC的相關規範中,明確定義,沒有所謂的認證(Certification)的機制,強調是屬於自我宣告以及買賣雙方的合約,強調產品家族觀念,並且重視製程品質管控(SPC)的要求,標準嚴格更甚於傳統以JEDEC為驗證主軸的消費型產品市場。

AEC驗證分類

|

Grade |

Ambient Operation Temperature Range |

|

0 |

-40°C to +150°C |

|

1 |

-40°C to +125°C |

|

2 |

-40°C to +105°C |

|

3 |

-40°C to +85°C |

AEC-Q系列與JEDEC 47的比較

|

Description |

JEDEC 47 |

AEC Q100 |

|

Test items |

以試驗項目為主 |

自開發至試驗 |

|

Test sample size |

相對較少 |

相對較多 |

|

Test duration / cycles |

較短 |

較長(以使用壽命回推) |

|

Temperature |

採用產品Tj |

採用環境Ta |

|

Data collection |

以承認為主 |

自產品開發開始 |

|

Family application |

有定義 |

定義含括範圍 |

|

Engineering change |

明確定義 |

明確定義 |

|

Life prediction |

說明較簡易 |

明確定計算方式 |

|

SPC calculation |

較少 |

強調應用 |

|

Pb-Free consideration |

較少 |

納入驗證標準 |

|

DPA process |

未提及 |

納入驗證標準 |

|

Criteria |

較簡易 |

允收規格明確 |

華證科技AEC驗證能力

華證科技著重於半導體產品領域驗證,整合FIB、故障分析、ESD靜電測試、硬件設計服務、可靠度試驗等,形成一個完整的服務網絡,協助客戶快速進入車用電子市場。

技術諮詢窗口

鍾小姐 / 工程處 / 03-6669700 ext. 6201

蘇先生 / 硬件評估與整合工程 / 03-6669700 ext. 6261