可靠度測試加速應力因子

Accelerated stress factor for reliability testing

可靠度加應力因子因產品使用方式或使用環境不同有所區分,常見的有電力負荷(Electrical Load)、溫度(Temperature)、濕度(Humidity)、壓力(Pressure)、汙染物(Contamination)、機械應力(Mechanical Stress)…等。加速因子的選擇必須優先考量使用的地區與環境,並確認產品的臨界水準(Criteria、Limitation),以規劃適當的試驗條件,避免產生過度惡化失真現象。下表為常用的應力因子與對應的使用參考,可作為產品設計參考外,亦可轉換成早夭品篩選技術,確保出貨產品的品質保證水準。

| Factors |

Description |

| Electric load |

The operation conditions, such as voltage, current, electric power and the combination of these conditions. |

| Temperature |

Base on Arrhenius's general formula, the relationship between relative lifetime and temperature. |

| Humidity |

Resin molded devices are water permeable and cause the malfunction with temperature. |

| Mechanical Stress |

Usually caused by transportation、machine installation and mechanical damages. |

| Static Electricity |

Electrostatic discharge, includes HBM, MM, CDM test etc. |

| Repeat Stress |

A stress is repeatedly applied may be stronger than steady stress. |

| Others |

Sunlight, dust, corrosion, chemical... ...etc |

華證科技專注於半導體產品可靠度驗證與分析服務,提供客戶完整的解決方案,並由業界經驗豐富之專業人員加入團隊,提供正確且有效的測試服務。實驗室的服務範疇種類包括:

- ESD靜電測試

- 晶片老化板之設計與製作

- 晶片壽命老化試驗 (HTOL / LTOL)

- 環境可靠度應力試驗

- 晶片早夭篩選 (ELFR)

- 車用電子驗證 (AEC-Q系列)

- 產品壽命預估

華證科技提供晶片一條龍完整驗證服務。此外,團隊專業人員並提供教育訓練、免費的實驗規劃、技術諮詢等,協助客戶產品開發階段順利進行。

除台灣新竹實驗室外,並於上海金橋、浦江與安徽合肥建置完整實驗服務,提供全方位的服務效能。未來將持續擴充實驗設備種類與數量,成為半導體可靠度測試的最佳夥伴。

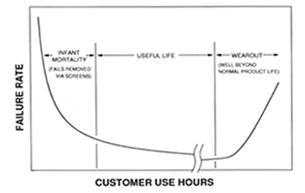

產品可靠度又稱為信賴性或可靠性,廣泛的定義為「產品在既定的時間內以及特定的工作環境下,執行特定性能或功能,並且圓滿成功達成任務的能力」。換句話說,可靠度指的是推估產品銷售後可使用的時間,而可靠度測試的目的在於透過給予產品適當的加速應力條件(Accelerated Stress Conditions),以縮短模擬驗證的時間,並以適當的壽命預估模式,取得有效性與正確性。

產品可靠度又稱為信賴性或可靠性,廣泛的定義為「產品在既定的時間內以及特定的工作環境下,執行特定性能或功能,並且圓滿成功達成任務的能力」。換句話說,可靠度指的是推估產品銷售後可使用的時間,而可靠度測試的目的在於透過給予產品適當的加速應力條件(Accelerated Stress Conditions),以縮短模擬驗證的時間,並以適當的壽命預估模式,取得有效性與正確性。